Together with a special division at Bayer, we developed the revolutionary ATLAS® rope as long ago as the 1960s. The cordage comprises monofilaments and multifilaments. Polyamide monofilament ropes have for years been serving as mooring lines for meeting the toughest requirements with outstanding characteristics such as UV resistance, abrasion resistance, suitability for winches and high breaking loads.

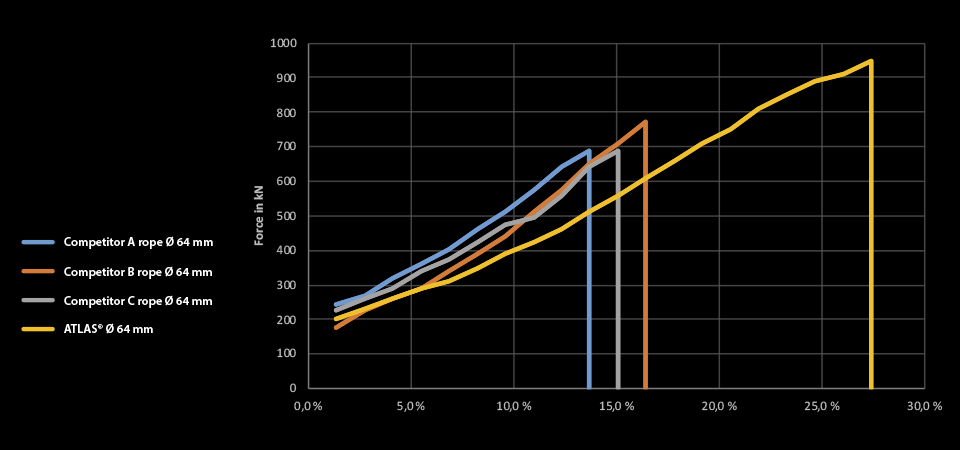

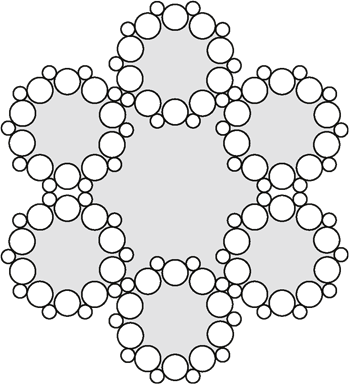

ATLAS® ropes are synthetic stranded ropes which combine the attributes of wire ropes and fibre ropes. They are dimensionally stable, flexible, require no maintenance, and are resistant to corrosion and seawater. Their elongation characteristics lie roughly between those for steel wire and polyamide. ATLAS® ropes have been proving themselves for many years in harsh everyday conditions on the world‘s biggest container vessels, multipurpose vessels and cruise ships.

Coiled ATLAS® ropes are perfect for reeling onto mooring winches. They possess an outstanding bending cycle strength and can be stowed when damp. Even acids and oils cannot affect the material.

Their excellent abrasion resistance is particularly worth mentioning. After a short period of use, the initial friction causes a kind of fluff to develop around the rope, which enables it to slide over winches and rollers with an especially low level of abrasion.

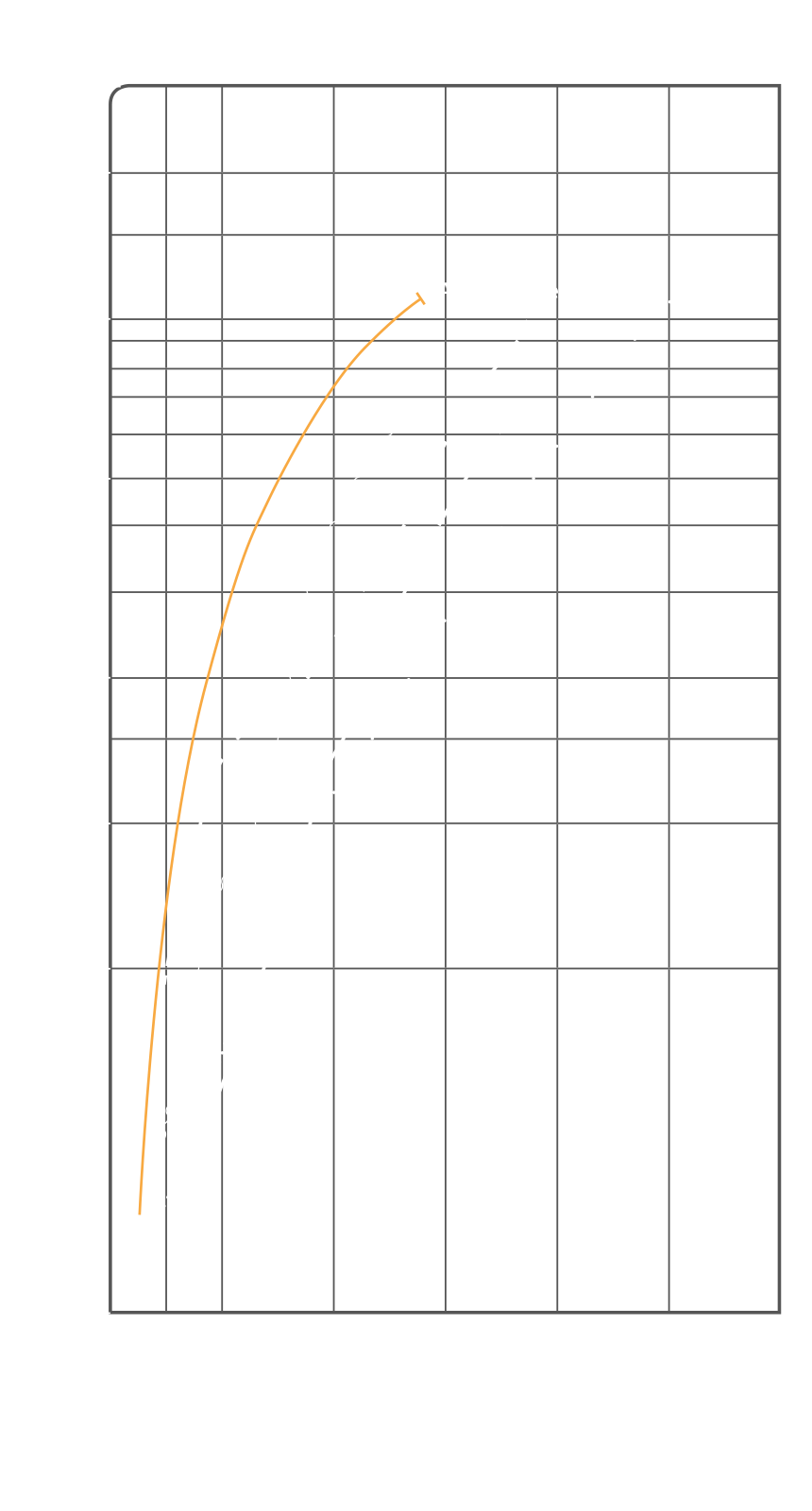

A surprising degree of elasticity, high tear strength and a remarkable resistance to corrosion and seawater result in an extraordinary longevity. Even after ten years of use, ATLAS® ropes still have a residual tensile strength of up to 85%.

Overview technical data

ø 24 – 96 mm

kg / m 0.40 – 5.85 kg / m

MBL mp 13.0 – 190.0

MBL daN 127.50 – 1863.90

Making

Type of lay: cross with filling thread

Specific properties

Application: Shipping